Unlocking Growth: The Transformative Perks of Contract Manufacturing for Your Business

In today's fast-paced and highly competitive market, businesses are constantly seeking innovative strategies to enhance their productivity and drive growth. One such strategy that has gained significant traction is contract manufacturing. By partnering with specialized manufacturers, companies can tap into a wealth of advantages, allowing them to focus on their core competencies while benefiting from the expertise and resources of their manufacturing partners.

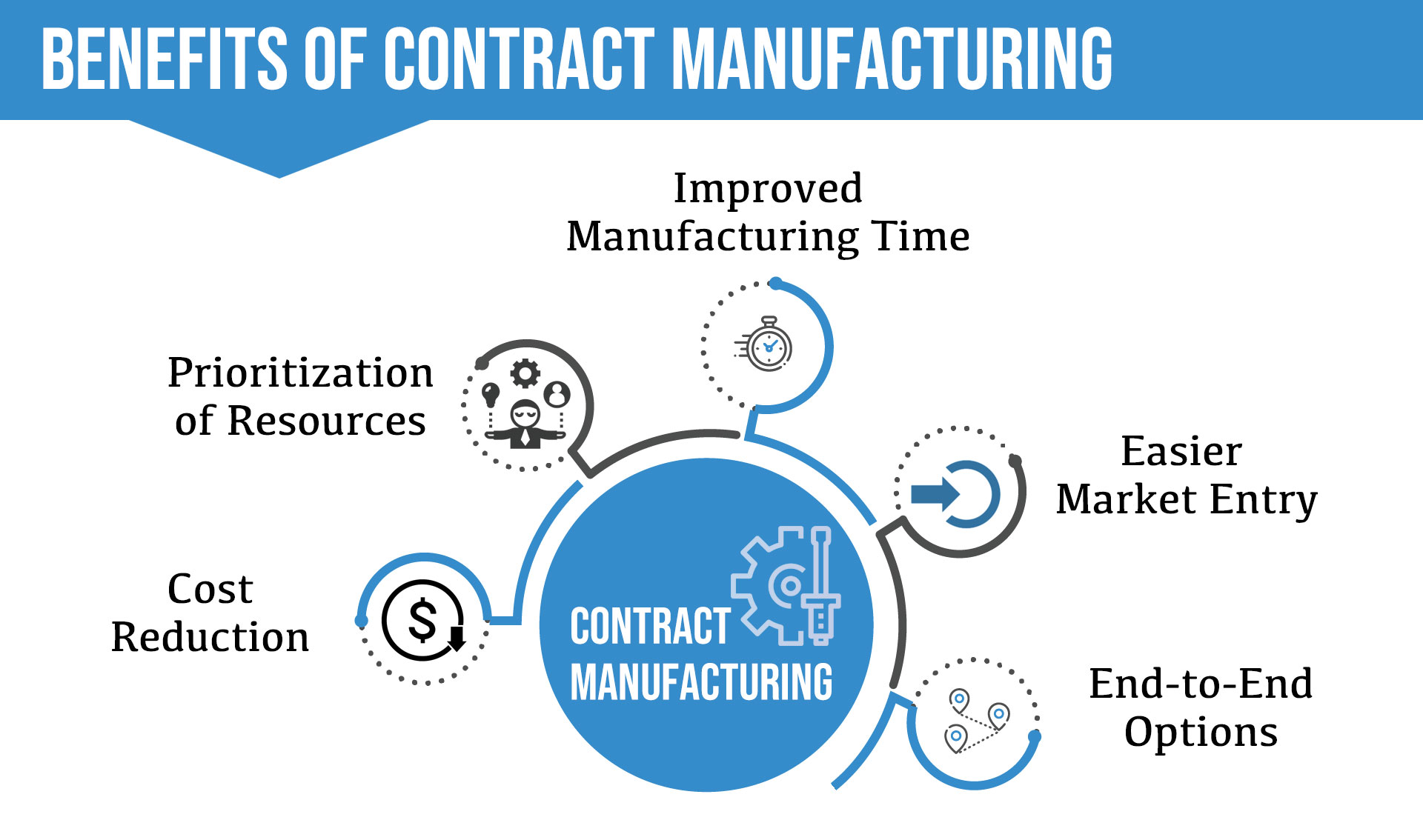

Contract manufacturing offers a flexible solution that can help businesses streamline their operations, reduce costs, and improve overall efficiency. As companies look to scale their production without the burden of heavy investments in facilities and equipment, embracing this model becomes more than just an option; it transforms into a strategic necessity. Understanding the various benefits of contract manufacturing can unlock new avenues for growth and innovation, providing businesses with the competitive edge they need to thrive in an ever-evolving landscape.

Understanding Contract Manufacturing

Contract manufacturing is an arrangement where a business outsources the production of its goods to a third-party manufacturer. This strategic approach allows companies to leverage the expertise and resources of specialized manufacturers, enabling them to focus on their core competencies such as design, marketing, and sales. By engaging a contract manufacturer, businesses can access advanced technologies and production techniques without the overhead costs associated with maintaining in-house manufacturing facilities.

The benefits of contract manufacturing extend beyond cost savings. Companies can quickly scale production up or down based on market demand, providing flexibility that is crucial in today’s fast-paced business environment. This adaptability allows businesses to respond efficiently to changes in consumer preferences or market trends, ultimately leading to improved responsiveness and competitiveness. Additionally, contract manufacturers often have established supply chains that can lead to enhanced production efficiency and reduced lead times.

Moreover, partnering with a contract manufacturer can open doors to global markets. By leveraging the manufacturer’s expertise in navigating international regulations and logistics, companies can expand their reach without the need to invest heavily in foreign production facilities. This collaboration not only facilitates entry into new markets but also helps in mitigating risks associated with currency fluctuations and geopolitical instability, providing a more stable foundation for growth.

Key Benefits for Businesses

One of the primary advantages of contract manufacturing is cost reduction. By outsourcing production, businesses can save significantly on overhead costs such as labor, equipment, and facility management. Contract manufacturers often have economies of scale that smaller companies cannot achieve on their own, leading to lower per-unit production costs. This allows businesses to allocate their resources more efficiently and invest in other critical areas such as marketing and research and development.

Another benefit is increased focus on core competencies. By partnering with a contract manufacturer, businesses can concentrate on their strengths, whether it's product design, sales, or customer service. Outsourcing production frees up valuable time and energy, enabling companies to innovate and improve their offerings without the distractions of managing a manufacturing facility. This strategic focus can lead to faster growth and enhanced competitiveness in the market.

Flexibility and scalability are also vital benefits that contract manufacturing provides. As market demand fluctuates, businesses can easily adjust their production levels without the burdens of maintaining large manufacturing operations. This adaptability is crucial for responding to changing market conditions and customer needs quickly. Businesses can scale up or down based on demand, ensuring that they can meet customer expectations without overextending their resources.

Navigating the Contract Manufacturing Process

Understanding the contract manufacturing process begins with selecting the right partner. Businesses must conduct thorough research to identify manufacturers that specialize in their specific industry and can meet their production needs. This includes evaluating the manufacturer's capabilities, technology, quality standards, and past performance. Building a strong relationship with the selected manufacturer is crucial as it lays the foundation for effective communication and collaboration throughout the production cycle.

Once a partner is chosen, the next step involves clear and comprehensive contract negotiations. This contract should outline all expectations, including production timelines, quality control measures, pricing structures, and confidentiality agreements. By addressing these key points upfront, both parties can prevent misunderstandings and establish a framework for accountability. Regular updates and discussions during this phase can help ensure that the partnership remains aligned with business goals.

Finally, once production begins, businesses should implement a system for monitoring progress and maintaining quality assurance. Regular check-ins, product inspections, and clear communication channels are essential in ensuring that the output meets the agreed standards. Engaging in continuous improvement practices can also foster a more productive relationship, ultimately leading to enhanced efficiencies and meeting market demands promptly.